Service

What Is 3D Printing Prototype?

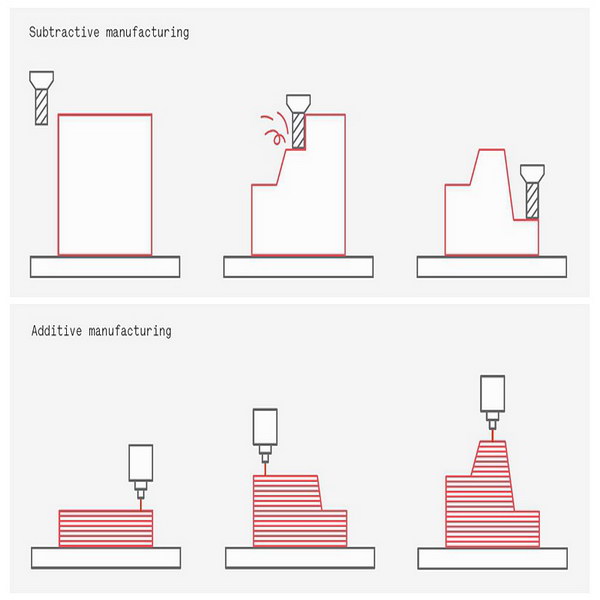

3D Printing is a broad term used to describe additive manufacturing, which includes a series of rapid prototyping technologies that combine multiple layers of materials to create parts.

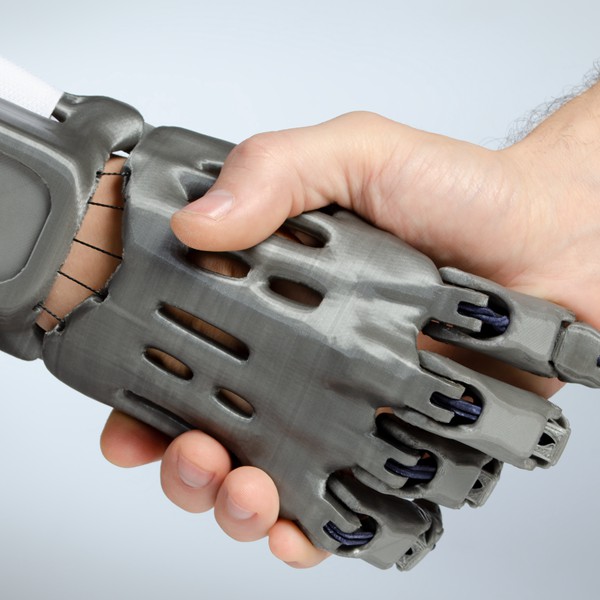

Rapid prototyping 3D printing is the quick, easy and cost-effective way to turn great ideas into successful products. These 3D printing prototypes not only help to verify the design but also find issues early in the development process and feedback directly on design fix, preventing costly changes once the product is in full production.

Why Choose JX For 3D Printing Service?

JX is an expert in the field of rapid prototyping manufacturing in China, providing a wide range of 3D printing services, including SLA 3D printing (Stereolithography), SLS 3D printing (Selective Laser Sintering).

At JX, We have a full team of dedicated engineers and project managers that will work with you to verify your CAD designs, product functions, dimensional tolerances, etc. As a professional prototype manufacturer, we deeply understand the prototype and production needs of any business. We strive to meet all specified times to deliver products with quality guarantees to our clients worldwide at affordable prices.

Benefits Of 3D Printing

● Shorten Delivery Times. Parts can typically be shipped within a few days, speeding up design iterations and time to market.

● Build Complex Geometry. Allows the creation of unique parts with more complex geometries and precise details without increasing costs.

● Reduce Manufacturing Costs. Drive to reduce production costs by eliminating the need for tools and reducing labor.

What Is SLA 3D Printing?

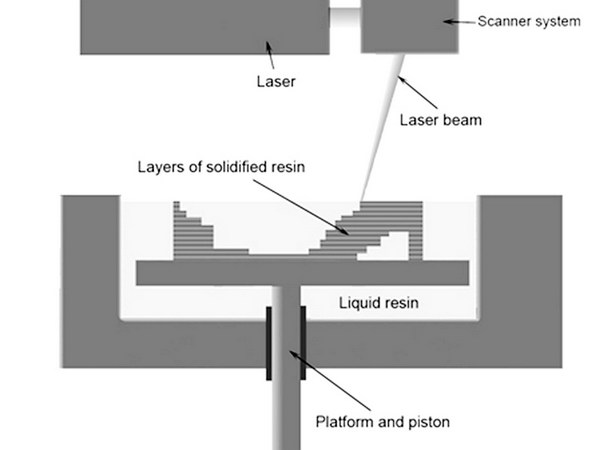

SLA 3D Printing (Stereolithography) uses an ultraviolet laser that draws on the surface of liquid thermoset resin to create thousands of thin layers until final parts are formed. A wide selection of materials, extremely high feature resolutions, and quality surface finishes are possible with SLA 3D Printing.

What Is SLS 3D Printing?

SLS 3D Printing (Stereo Laser Sintering) makes use of a high power optic laser that fuses small powder particles layer by layer to produce complex and durable geometric parts. SLS 3D Printing builds robust parts with filled Nylon materials, suitable for functional prototypes and end-use parts.

How Does SLA 3D Printing Work?

● Data processing, the 3D Model is imported into a slicing program of proprietary software, with support structures added as necessary.

● The STL file is then sent to print on the SLA machine, with a tank filled with liquid photosensitive resin.

● A building platform is lowered into the tank. The UV laser beam focused through the lens scans contour of the cross-section along the liquid surface.

● The resin in the scanning area solidifies quickly to form a single layer of material. Once the first layer has been completed the platform is lowered by 0.05–0.15mm with a fresh layer of resin covering the build surface.

● The next layer is then traced out, curing and bonding the resin to the layer below. Then repeat this process until the part is built.

How Does SLA 3D Printing Work?

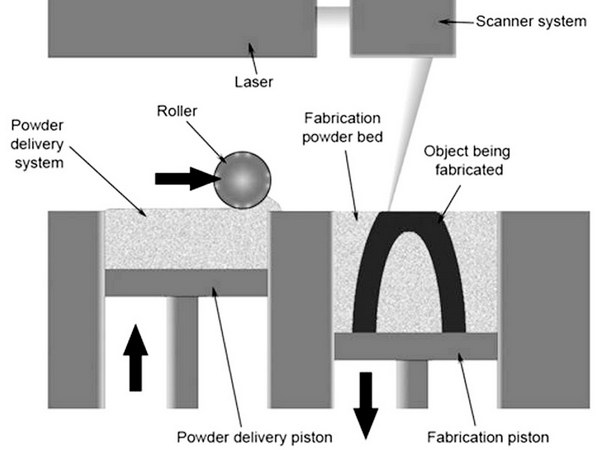

● The powder is dispersed in a thin layer on top of a platform inside of the shaped chamber.

● When heated just below the melting temperature of the polymer, a laser beam scans the powder according to the cross-section contour of the layer and sinters the power. The unsintered powder supports the cavity and cantilever of the model.

● When the sintering of a cross-section is completed, the thickness of the platform

decreases by one layer, and the laying roller spreads a layer of uniformly dense powder on it for the sintering of a new cross-section.

● The process is repeated until all layers are sintered to obtain the solid model.

How Does SLA 3D Printing Work?

Advantages of SLA 3D Printing

Lower layer thickness and higher accuracy.

Complex shapes and precise details.

Smooth surfaces and post-processing options.

Various material property options.

Applications of SLA 3D Printing

Concept Models.

Presentation Prototypes.

Prototyping Clear Parts.

Master Patterns for Silicone Molding.

Advantages of SLS 3D Printing

Engineering-grade thermoplastics (Nylon, GF Nylon).

Excellent mechanical properties and layer bonding.

No support structures, enabling complex geometries.

Temperature resistance, chemical resistance, abrasion resistance.

Applications of SLS 3D Printing

Functional Prototypes.

Engineering Test Parts.

End-use Production Parts.

Complex Ducts, Snap Fits, Living Hinges.

Ready to Get Started?

From prototype to production, our team of engineers is ready to help bring your idea to life.

Compare The Following Capabilities Of SLA And SLS To Choose The Right 3D Printing Service

3D Printing Vs CNC Machining: Which Is Right For Your Prototype And Production?