Service

Rapid Tooling

What is rapid tooling? Rapid tooling is a specialty service for making certain kinds of plastic injection mold tools and finished parts in a fraction of the time it takes to make full-production volume tools. It relies on optimizing the design, fabrication, and materials to achieve maximum production efficiency and minimal downtime.

How Does Rapid Tooling Work?

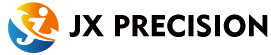

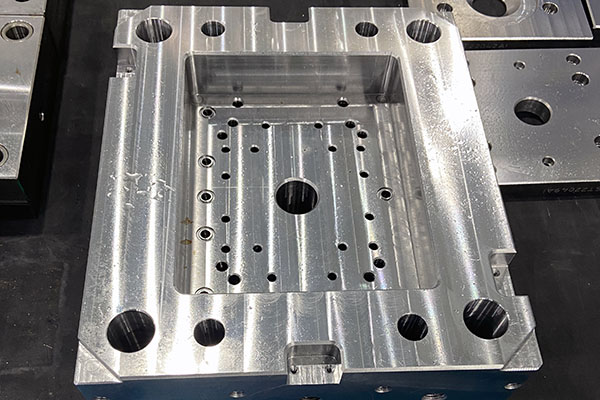

JX offers a unique rapid tooling system. A single master machinist is responsible for your tool from start to finish. Using modular mold bases and P20 tool steel, a machinist can produce a finished mold in as little as ten days from the approval of design drawings. These molds use standard plastic resins and fillers to make fully functional finished parts in relatively limited quantities. There are many advantages to rapid tooling. Finished parts can be used for prototypes, product testing and certification, and as bridge production towards higher volumes. Rapid tooling injection molding also helps our clients to limit their financial exposure to new designs.

What Are The Limitations Of Rapid Production Tooling?

In order to achieve rapid results, there are some necessary limitations to the kinds of tools and parts that can be made using this approach. These limitations don’t mean you get an inferior tool. Rather, we simplify the development process in order to achieve the shortest possible production lead time at the least expense.

● Simplicity

● Rapid tools are two-piece molds, with at most two cavities per mold. This means there are no extra sliders or hand-loaded inserts.

● The geometries must be relatively simple, not requiring sophisticated gate/runner systems or complex cooling channels.

● Simple geometries allow for basic ejector pin strategies.

● Simple geometries don’t require expensive MoldFlow analysis.

● Cold Runners

● Cooling circuits use standard cold runners, not hot runners.

● Surface Texture

● Rapid tools have as-machined surfaces, with minimal polishing or bead blasting.

● Modular Inserts

● Only the inserts are machined. They’re designed to fit into standard mold bases for ease of manufacturing and to reduce material usage.

● Standard Tolerances

● Tools are machined to DIN-27681-fine standards.

There may be other minor limitations depending on the project. We review every design in advance to ensure it meets our criteria for rapid production tooling.

Rapid Tooling Mold Material: Aluminum or Steel?

JX uses only P20 steel for rapid production tooling. We do this because P20 steel is as easy and fast to the machine as aluminum, using standard cutting tools and requiring no post-machining heat treatment. Such tools are called ‘semi-hardened’. It produces an excellent surface finish, and the raw material isn’t as prone to supply disruptions. P20 steel is also equal in price to aluminum per tool. But most importantly, it’s much more durable, making a better tool that can produce more finished parts. We believe there are no practical advantages to using aluminum over steel.

Why Choose Star As Your Rapid Tooling Company?

Rapid Tooling with Full Volume Production Quality

We never cut corners when it comes to making quality tools and finished parts. We’re able to give you rapid tools because we simplify the development process, while still providing the same quality workmanship and materials as full-volume production – at a much lower cost.

Industry-Leading Equipment, Uncompromised Testing

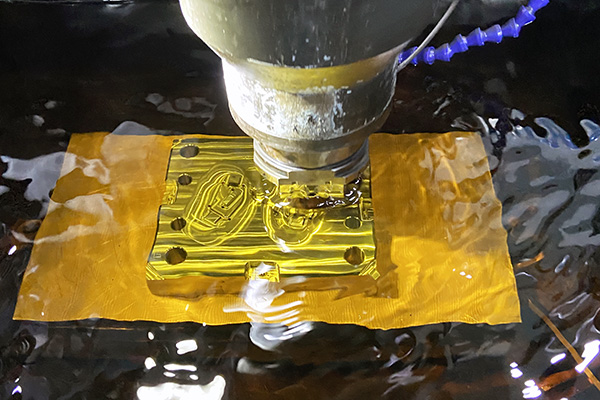

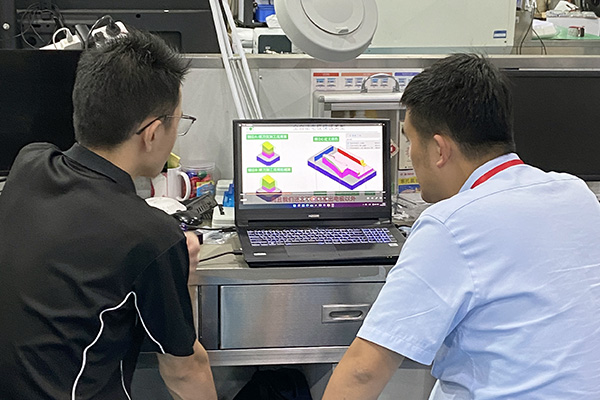

We pride ourselves on state-of-the-art positive material identification to ensure full compliance with your specifications. All work is done in-house with modern equipment using advanced management systems.

A Proven Rapid Tooling System

A single master machinist is assigned to your project, and they’re exclusively responsible for managing the entire toolmaking strategy to achieve the fastest possible turnaround. This proven system is streamlined and efficient.

Design for Manufacturing Support

Our goal is to make your product the best it can be. To that end, we proudly offer design for manufacturing (DFM) support with every quote, if needed. If you’re unable to visit our facilities in person, we offer detailed video files showing all production steps, plus video conferencing and general support.

Intelligent Pricing for Every Project

We never require a minimum order volume or minimum dollar value, and most jobs are quoted in 24 hours or less.

Our Material Verification

We use X-ray fluorescence and spectrophotometry to measure the precise molecular composition of all the raw materials we use for your tooling. You can be assured you get exactly the material grade you specify. Our attention to detail doesn’t stop when your mold is completed. We’re not satisfied until your finished parts have been fully verified in our modern quality control metrology lab.

Toolmaking Tolerances and Finishing Guidelines

Unless otherwise specified by you, our standard tolerances conform to DIN-2768-1-fine. Surface finishes for the core and cavity of mold tools can be made according to the classification system of the Plastics Industry Association using their general surface finishing guidelines. If you need the finest in rapid toolmaking services, contact JX today.

Quote Now to Start Your CNC Machining Project

Complete CNC machining services from prototype to production ensure high quality, fast delivery and competitive prices.