Industry

World-class Aerospace Machining Services: Customized, cost-effective and high quality

Standing with 19+ years of expertise and an impeccable track record, DEK offers a wide range of precision CNC machining services to the global aerospace industries including NASA, Raytheon, UTC, and Boeing.

The very nature of aerospace applications is such that a single small error or imperfection can trigger disastrous consequences. So, in order to ensure accuracy and accountability, we rely on CNC machining along with a team of highly-skilled veteran engineers. We provide the unfailing precision aerospace components and prototypes within exceptionally tight tolerances to exact specifications while maintaining the rigorous standard of ‘in-process communication’ and ‘on-time delivery’.

Our Aerospace Machining Advantages

With industry-recognized AS 9100 | ISO 9001:2015 certification, we guarantee the optimal performance of our end-products.

Our ultra-modern CNC machining fully meets the stringent needs of the diverse customer base of the aerospace industry by providing close-tolerance (±0.001mm), precision-machined components.

We work with a broad array of plastics, metals, alloys, including commonly used materials such as aluminium and titanium.

Specialized technicians along with veteran engineers rigorously monitor every stage of the aerospace machining process.

We render complete services from concept/design development to manufacturing, including heat- treating, plating, painting, testing, precision cleaning, and finishing.

We have strict privacy policies and we manage export-controlled projects with extreme security.

DEK: Your One And Only Stop For The Best Aerospace CNC Machining

shop has imbibed the proven methods to deliver quality, performance, and reliability on each and every project. Our engineering team has extensive experience related to a variety of aviation, military, and stratospheric specifications.

We have a complete range of equipment including the 3-axis CNC machine, 4-axis CNC machine, 5-axis CNC machine, Swiss screw machine, CNC lathe, EDM machine, etc, and numerous material supply chains, which are sufficient to deal with any CNC machined parts, whether plastic or metal, complex or simple. Our mastery over industry-recognized materials such as aluminum, titanium, stainless steel, exotic alloys, and high-temperature plastics makes us the rising star in aerospace component manufacturing. We can source all metals and diverse materials from your approved vendor or from our subcontractors, who are capable of providing actual mill certifications. We manufacture relatively standard parts as well as parts having complex geometry that is widely considered difficult to produce. Our capabilities include CNC turning, CNC milling, Swiss precision turning, dimensional CMM inspection, etc with tolerances as tight as ±0.001mm. To ensure proper traceability on all the manufactured products, we run a full ERP system.

Diversified Capabilities Of DEK's Aerospace Machine Shop

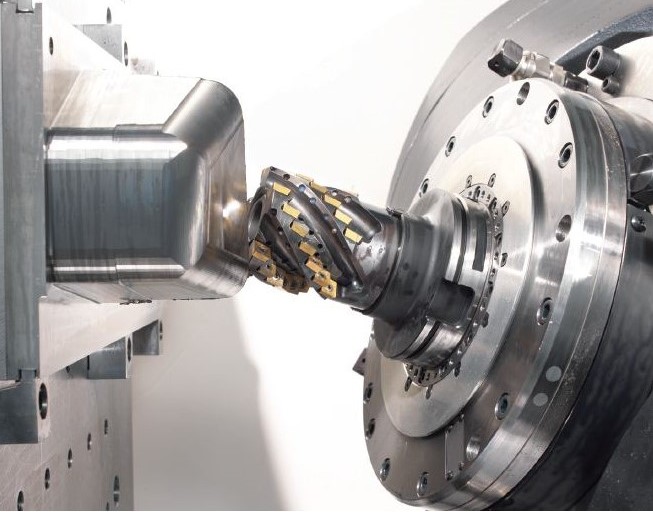

5-axis CNC Machining

Basically, most industrial machining works on three fundamental axes, X, Y, and Z but a 5-axis CNC machining incorporates additional 2 rotary axis movements (A and B) which render it the ability to become multi-directional. It helps to reduce production time significantly by reducing multiple setups which, in turn, helps in reducing errors.

Many companies advertise about true 5-axis simultaneous machining while, in fact, they employ other versions such as 3+2 axis (3 axes for machining and 2 axes for positioning) and in some cases 4+1 (4 axes for machining and 1 axis for positioning).

Considering the varying complex contours of aerospace parts, it is a sensible choice to configure them using 5 Axis CNC machines. At DEK you’ll get an unmatchable service of true 5-axis simultaneous machining.

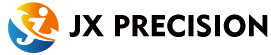

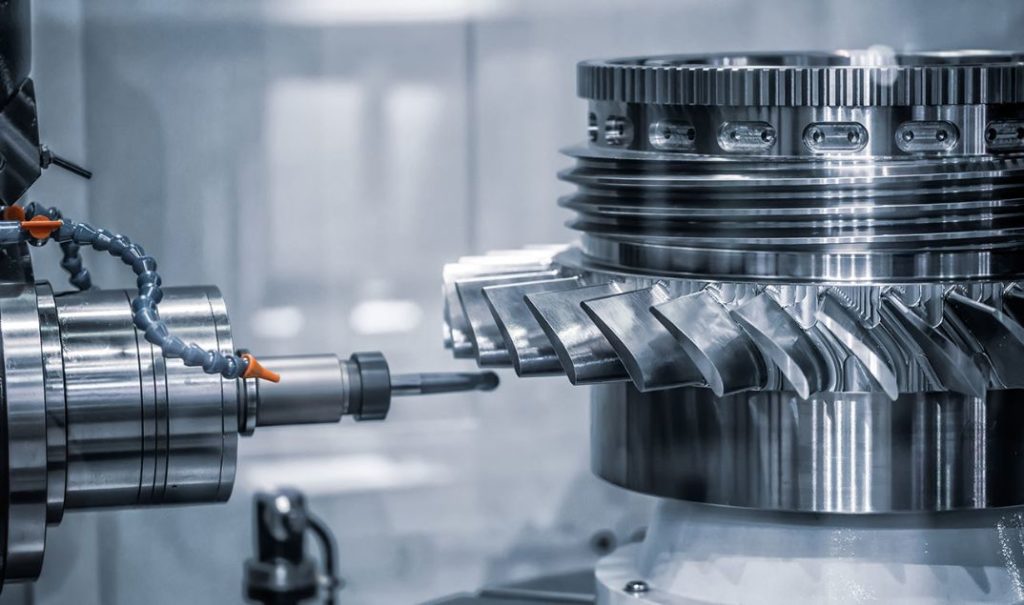

CNC Turning (Vertical and Horizontal)

DEK’s CNC-turning services incorporate cutting-edge precision technology to ensure speedy production along with tight tolerances. CNC turning is the best application for the parts with rotational symmetry. Our CNC turning processes include cutting, facing, threading, forming, drilling, knurling, broaching, and boring. Our 5-axis CNC Lathe machine, which turns materials at high speed while cutting away excess material, uses multiple high-speed spindles and is controlled by CAD (Computer Assisted Drawing) software. We follow blueprints to make sure the CNC Lathe produces precise specifications for small and large scale productions concerning all types of metals/alloys and the majority of plastics.

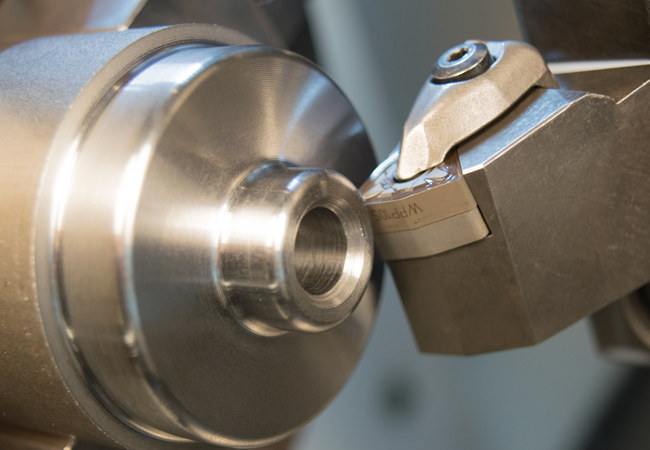

CNC Milling (Vertical and Horizontal)

DEK’s CNC-milling services incorporate cutting-edge precision technology to ensure speedy production along with tight tolerances. With a maximum 2,000 RPM of spindle speed, 8,000 RPM of rigid tapping speed, and 50 meters per minute of traverse speed, we can help you create designs from simple straight lines to complex geometric shapes with great reliability and repeatability. Our 5 Axis CNC machining can easily suit the high performance and rigorous demands of the aerospace industry. We can create G-codes from both a 3-D CAD file (.DWG) and a hard-copy print. We accept a wide array of file formats including .PDF, .DXF, .IGS, .SLDDRW, .SLDPRT, .STP etc. However, providing a 3D CAD file can cut the time spent on programming CNC milling code.

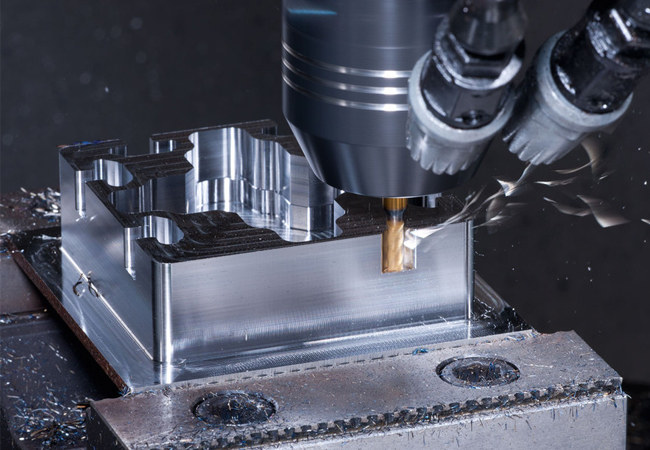

Swiss Precision CNC machining

We offer Swiss Precision CNC machining services to manufacture critical, small, and intricate aerospace components quickly with an exceptional degree of accuracy. Our high-tech Swiss machining lathes can rotate a component along 7+ different axes, allowing for the precise cut with tight tolerances. Furthermore, our Swiss turning equipment can do several operations simultaneously in multiple zones with reduced cycle-times, whereas a traditional lathe typically does a single operation at a time. We operate this technology using Part Maker CAD/CAM software. The additional capabilities of our Swiss CNC machining include deep-hole drilling, slotting, threading, and hobbing without multiple setups. Our Swiss CNC machining services can handle both high- and low-production volumes concerning different types of metals/alloys/plastics with a quick turn-around time.

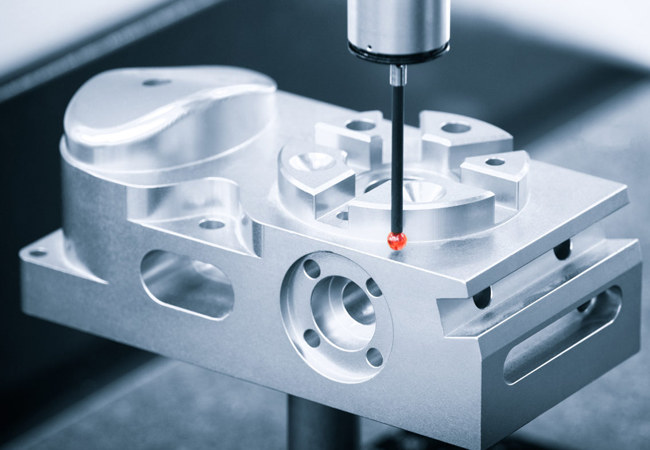

Dimensional CMM inspection

CMM inspection is an important milestone for all aerospace engineering projects where precision and safety go hand in hand. This process ensures that your 2D drawings and CAD models are fully realized in terms of reliability, accuracy, and safety. However, very few machine shops have the technology and expertise to carry out proper third party inspection. Inside our temperature/humidity controlled lab where there is no possibility of thermal expansion, we utilize several contact and vision CMM systems to render precise dimensions of any component along X, Y and Z-axis. For the components that very tiny and fragile to employ contact measuring, we employ vision or non-contact CMMs that work with laser.

DEK’s CNC-milling services incorporate cutting-edge precision technology to ensure speedy production along with tight tolerances. With a maximum 2,000 RPM of spindle speed, 8,000 RPM of rigid tapping speed, and 50 meters per minute of traverse speed, we can help you create designs from simple straight lines to complex geometric shapes with great reliability and repeatability. Our 5 Axis CNC machining can easily suit the high performance and rigorous demands of the aerospace industry. We can create G-codes from both a 3-D CAD file (.DWG) and a hard-copy print. We accept a wide array of file formats including .PDF, .DXF, .IGS, .SLDDRW, .SLDPRT, .STP etc. However, providing a 3D CAD file can cut the time spent on programming CNC milling code.

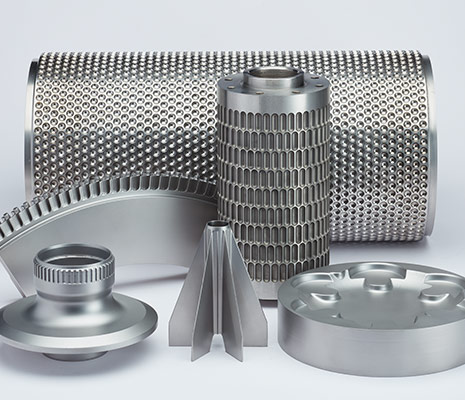

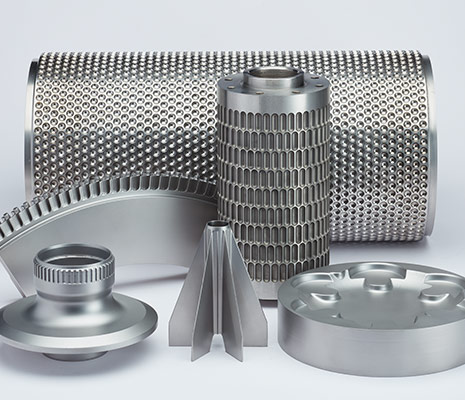

Some Of The Aerospace Components/Parts We Can Manufacture

Guidance Fins

Aircraft Seat Frame

Flanges

Retainer Rings

Machined Reflector

Hinges

Check Valve

Control Valve Housing

Battery Core

Hydraulic Pump Rotor Shaft

Large Shafts

Helicopter Rotor Hubs

Separation Disc

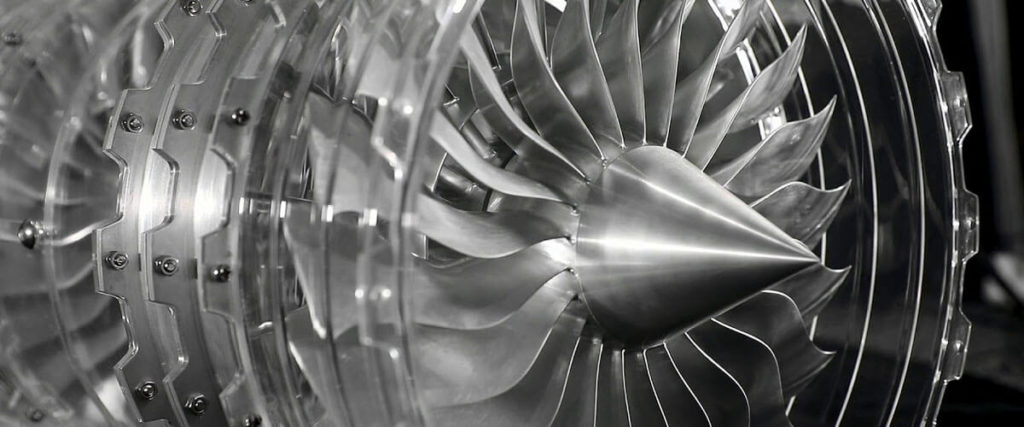

Gas Turbine Compressor Cases

Rotors

Actuators

Axles

Gearbox Components

Piston

Oil/Fuel Filtration Components

Electrical Connectors

Fuel Access Panel

Transmission Housing And Components

Materials for Aerospace CNC machining

Material choice is a key element in aerospace engineering. Essentially, the best materials for aerospace projects must possess the properties of being lightweight, highly temperature-resistant, damage-tolerant, and durable.

Some of the most preferred materials for the aerospace industry which lie within the ambit of our expertise include:

Aluminum

Aluminum has a long history of being the most dominating metal in aerospace applications. For some time in the past 70% of the aircraft used to be made of aluminum. Compared to other metals or steels, it is lightweight, cheaper, state-of-the-art, and easily-workable, thereby contributing to fuel-efficiency as well as weight allowance.

Alloys of aluminum are also recognized in terms of their strength and corrosion-resistance, making them the ideal materials for machinery and engine components.

In spite of the introduction and advancement of other refined materials (new alloys and composites), aluminum and its alloys still have a decent range of applications inside the aerospace industry.

Titanium

Titanium is also a widely recognized material because of its low density, strength, and corrosion-resistance. Titanium came into the scene with the inception of cold-war and in the 1950s it gained a strong foothold in the aerospace industry. Although it is comparatively heavier than aluminium, its impressive strength implies that you may use less of it. Ti6Al4V is the popular grade of titanium.

Along with the introduction of various titanium alloys, military aircrafts are opting for titanium to manufacture stronger and lighter components.

Titanium is taken as the material for engine components, hydraulic systems, machinery, and aircraft structural frame.

Tungsten

Superalloys (High-performance alloys) are the group alloys that demonstrate unparalleled corrosion/oxidation resistant characteristics and retain their mechanical strength, stiffness, and dimensional stability at very high temperatures. Superalloys can become the ideal choice for a jet engine’s hottest sections, compressor, and turbine stages.

Alloys of aluminum are also recognized in terms of their strength and corrosion-resistance, making them the ideal materials for machinery and engine components.

In spite of the introduction and advancement of other refined materials (new alloys and composites), aluminum and its alloys still have a decent range of applications inside the aerospace industry.

Composite Materials

The use of composite material (mainly CFRP-Carbon Fiber Reinforced Plastic and GFRP-Glass Fiber Reinforced Plastic) in the aerospace industry has been increasing rapidly since 1987. They are easy to handle, design, shape, and repair. They also play an important role in fuel efficiency and weight reduction. Previously, they were used for cabin components or light structural pieces but now they are also being used for landing gear, engines, wings, and fuselage skins.

Apart from these materials, we can work with varieties of other materials such as stainless steel, copper, chromium, brass, bronze, beryllium, manganese, molybdenum, platinum, graphite, etc. Our technology and team are capable of machining almost any of your specified materials.

Guide To Aerospace Machining & Buying F.A.Q

Aerospace machining enables us to process complex part designs with utmost efficiency, precision, and accuracy.

It’s easy to achieve up to 99.5% quality precision and tight tolerances for your parts to achieve high customer satisfaction.

This FAQ guide will help you understand aerospace machining completely and how DEK performs it with utmost precision and care.

You will also learn what custom options DEK offer and what overall benefits you will get from aerospace machining.

What Is Aerospace Machine Shop?

The aerospace machine shop is a facility that offers every aerospace machining related service to its customers internationally.

Like DEK is an aerospace machine shop and offers:

● 5-Axis CNC

● Engineering Services

● All Types of Milling, Machining, and Turning

● Horizontal and Vertical Machining

● Multi-Axis Complex Machining

● And many more

Furthermore, an aerospace machine shop offers high precision results based on quality standards in a complete temperature and dust-controlled environment.

The aerospace machine shop specializes in machining parts related to aerospace, defense, military, and general industry.

It’s important for aerospace machining shops to be technologically enhanced, innovative, and adopt the latest state-of-the-art machining equipment.

Moreover, the aerospace machining shop can work with any type of metal, including complex ones used in the aerospace field.

The aerospace machining shop can understand aerospace machining components’ critical nature, knowledge, and level of attention required to achieve optimal performance and precision.

An advanced aerospace machine shop must be able to:

● Process and precisely cut the complex surfaces with high-speed machining

● Using 5-Axis machining to fabricate parts rapidly

● Feature-based machining

● High-accuracy simulation

● Fabricate mission-critical and flight-critical aerospace components

As an aerospace machine shop at DEK, you can achieve nothing less than perfection.

The perfectly controlled aerospace machining process in the fabrication of complex parts to achieve high quality and cost-effective parts is what aerospace machine shop do the best.

What Are The Structural Components Of Aerospace Machining?

The structural components of aerospace machining belong to a class of lightweight aircraft and spacecraft parts.

That’s the reason behind 5-Axis CNC technology adoption in aerospace machining.

Furthermore, it also reduces the overall steps involved in aerospace machining.

The complete aerospace machining control, along with the high-speed fabrication, eliminates the time to manufacture parts.

Optimizing the whole aerospace machining process helps you:

● Reduce the raw material waste

● Minimize the waste of resources and energy

● Eliminate unnecessary steps

● Increase fabrication time

● Maximize productivity

● Achieve more efficiency

● High-speed and precise machining for complex parts

Moreover, aerospace CNC machines’ high accuracy and acceleration response define the dynamic response of part fabrication efficiency.

That saves time without sacrificing quality, performance, accuracy, and precision.

Increasing aerospace machining speed increases productivity by eliminating times.

Rapid and precision aerospace machining is the future and key to high-speed part fabrication.

Furthermore, high-speed aerospace machining reduces the cost and compresses production time by increasing flexibility.

How To Achieve Superior Sustained Dynamic Accuracy Through Aerospace Machining?

In an attempt to reach high speed and perfect manufacturing in aviation engineering, dynamic accuracy plays an important part.

Dynamic accuracy and precision have become the core requirements for many aerospace parts.

You can achieve a perfect aerospace application design through accurate and perfectly detailed machined parts.

Fabricating parts within the strict quality-controlled environment enable you to achieve superior sustained dynamic accuracy.

It’s important for critical parts manufacturing to maintain quality and a high volume of precision.

The following can help you achieve the superior sustained dynamic accuracy of parts you required:

● Improving the accuracy

● Meeting standards

● Optimizing aerospace machining processes

● Accurate measurements

● Proper analysis

● Handling part complexity

● Rapid identification of errors

● Quality control

● Design improvement of aerospace machining

Moreover, manufacturing based on tight tolerances even for the complex parts is important to achieve dynamic accuracy.

An optical balance of aerospace machining’ availability, reliability, performance, productivity, repeatability, and programming is required to maintain in-order-to achieve the desired accuracy.

Most importantly, it is critical for parts to meet the standard measurements of a model to achieve dynamic accuracy.

It’s a fact that the more accurate the aerospace machined part is, the more superior its dynamic accuracy will be.

How Aerospace Machining Is A Cost-Effective Solution For Complex Parts?

It is important to maintain aerospace machining’s overall cost for your parts.

It’s also important because ignoring some factors related to aerospace machining can lead to extreme costs for your parts.

When designing and machining complex parts, the overall production time, material selection, and complexity must be controlled to make aerospace machining cost-effective.

For example, our aerospace machining is rapid, fully optimized, and precise at DEK.

As well, DEK offers all its aerospace machining services in cost-effective manners.

By considering the following factors, you can make aerospace machining cost-effective:

● Material Selection

● Part Complexity and Designing

● Part Customization

● Accuracy and Precision

● Flexibility in Rapid Aerospace Machining

At DEK, we optimize the aerospace machining performance and reduce the chances of defects to null, reducing cost.

It is important to never compromise on quality, performance, and precision in aerospace machining, especially for complex parts.

The technologically enhanced aerospace machining enables you to have affordable, dependable, and efficient solutions for your parts.

Furthermore, the selection of cost-effective materials for aerospace machining is productive.

Most importantly, reducing the number of defects and errors along with a fast fabrication process is proven a key to cost-effective solutions.

What Materials Are Used For Aerospace Machining?

Millions of parts belong to the aerospace industry and come into existence through aerospace machining.

Machining these parts require the use of several materials.

These materials’ quality depends on two key properties: strength and weight.

It’s important for an aerospace machined part to be robust and withstand versatile conditions.

The selection of lighter materials can lead to lighter parts that can reduce planes’ overall fuel consumption.

Hence the following are some lightweight and strong materials that are considered ideal for aerospace machining:

● Material Selection

● Part Complexity and Designing

● Part Customization

● Accuracy and Precision

● Flexibility in Rapid Aerospace Machining

At DEK, we optimize the aerospace machining performance and reduce the chances of defects to null, reducing cost.

It is important to never compromise on quality, performance, and precision in aerospace machining, especially for complex parts.

The technologically enhanced aerospace machining enables you to have affordable, dependable, and efficient solutions for your parts.

Furthermore, the selection of cost-effective materials for aerospace machining is productive.

Most importantly, reducing the number of defects and errors along with a fast fabrication process is proven a key to cost-effective solutions.

Aluminum

Aluminum: It is completely machinable and provides excellent resistance to extreme temperatures and corrosion.

Aluminum is much lighter than titanium and cost-effective. Additionally, it is suited for a vast library of aircraft components but half as strong as titanium.

Aluminum offers weight allowance and fuel efficiency and also cheaper.

Titanium

Titanium: It is approximately 25% more robust and 40% lighter than steel. It’s appropriate to use titanium for external parts.

It is corrosion-resistant and mostly used for engines and other complex parts.

Steel

Steel: It is considered ideal for functional aircraft parts. Stainless steel is the primary materials for many aerospace applications, including:

● Tanks

● Exhaust Components

● Panels

● Engine Parts

Aerospace machining is able to process the parts that require extremely detailed design, so the materials must be superior in strength, resistance to wear, and reliability.

Furthermore, manufacturers use bronze, copper, platinum, zinc, and many other superalloys for aerospace machining.

In the aerospace industry, customers prefer materials that provide resistance against high temperatures, oxidation, deformation, and creep, which led us to superalloys.

These superalloys include nickel, cobalt, and iron to strengthen parts’ overall quality and performance.

What Are The Advantages Of Aerospace Machining?

Whenever it comes to aerospace parts and structures, aerospace machining is the most useful to manufacture them.

Aerospace machining has many benefits for a long period of time.

Aerospace machining fabricates parts that require no room for error as well as require utmost precision.

The following are some advantages of aerospace machining:

● High Accuracy of Parts

● Precision Manufacturing

● No Room for Error Due to Fully Optimized Machining Processes

● Ability to Manufacture Complex Parts

● Eco-Friendly

● Pollution-Free Solution

● Offer Part’s Longevity

● Cost-Effective Solution

● Rapid Production

● Efficient Machining Tools

● Improve Quality Control

● Higher Machine Accuracy Capabilities

● Offer Versatility and Repeatability

● Quick and Flexible to Manufacture Lightweight Parts

● Fewer Steps with Relational Accuracy

● Better Surface Finish

It is no denying that aerospace machining shaped the aerospace industry through its advanced and precision manufacturing.

Aerospace machining is optimized and has 10% lower electricity costs than any other machining.

Aerospace machining is considered the aerospace industry’s future and already started to shape it.

Moreover, aerospace machining offers much more to offer based on what you require.

What Is The Aerospace Machining Process?

The aerospace machining process is consisting of multiple material processing techniques.

It’s technologically enhanced and used for fabricating parts that require precision and accuracy.

Cost-effectively producing high strength parts is a key feature of the aerospace machining process.

The aerospace machining process is performed in a fully controlled environment to maximize the output.

It’s an automated process, so it requires a soft file that contains the structure, shape, and design of the required part.

All machining is performed based on that soft file, so it is crucial to understand its importance.

Afterward, the right aerospace machining process is selected based on your requirements.

Manufacturers select the 5-Axis CNC for fast and most advanced machining and get precision and tight tolerances for your aerospace parts.

Moreover, 5-Axis CNC reduces the overall machining steps to make it optimized and fast.

Advanced aerospace machining also eliminates non-value-added to make it rapid.

Furthermore, manufacturers perform grinding, milling, or drilling only if the part requires.

Managing the quality at each stage and following standard procedures is important because a single imperfection or malfunction in part fabrication can lead to failure and disastrous results.

Hence, CNC machining is utilized in aerospace machining to eliminate the risk of error and achieve high-precision parts.

What Is Aerospace Machining With 5 Axis CNC?

It is important to understand that aerospace machining differs from standard CNC machining.

Furthermore, manufacturers require it where parts require incredibly tight tolerances.

The advanced CNC machining process helps achieve fast production and fabrication of aerospace parts.

Aerospace machining is properly controlled and offers durability through its effective 5-Axis CNC machining process.

Moreover, the aerospace industry is aware of the importance of 5-Axis CNC machining to maintain exceptional quality and to improve part performance.

Moreover, the aerospace industry is aware of the importance of 5-Axis CNC machining to maintain exceptional quality and to improve part performance.

5-Axis CNC machining enables us to get:

● High Precision Manufacturing

● Variety of Parts of Different Complexity

● Lightweight Materials of High Strength

● Extreme Accuracy

● Eliminate the Chances of Human Error

● Fabricate Complex Geometries

Considering the aerospace parts’ variation along with the complexity, 5-Axis CNC makes sense to achieve the utmost precision and tight tolerances.

The use of 5-Axis CNC in aerospace machining allows for continuous reconfiguration of parts.

Moreover, its ability to handle aerospace parts’ complex geometries is ever-evolving and continuous.

Additionally, 5-Axis CNC enables us to the mill, drill, and manufacture parts according to the specifications.

It copes better with the scope and technicality of aerospace parts. It easily suits the high-level demands of the aerospace industry.

5-Axis gives us the freedom that is impossible to achieve with 3-Axis and 4-Axis CNC that give us the design and geometry limitations.

What Is The Importance Of Tight Tolerances In Aerospace Machining?

Aerospace parts have only one fundamental requirement, and that is to meet tighter tolerances while increasing the material removal rates.

Moreover, aerospace machining helps in achieving this fundamental requirement.

Achieving tight tolerances is obvious for structural parts and sometimes requires tough machining.

Achieving tight tolerances is obvious for structural parts and sometimes requires tough machining.

Tight tolerance of ±0.001mm is acceptable for aerospace parts and required to maximize the part performance and quality.

When determining the tolerance limit for aerospace parts, always remember that the tighter the tolerance is, the better the part will fit.

Part’s efficiency and reliable functionality completely depend on its tolerance.

Remember, always going for the tightest tolerance can increase the overall cost, and perfectly manufactured parts can cost you more.

Tighter tolerances of parts eliminate the risk of its failure, jam, slip, or others.

There should not be even a slight margin of error in aerospace parts because of a single imperfection and cost you millions.

Hence, precision and tight tolerance are what aerospace machining is about.

How Does Aerospace Machining Deal with Complex Part Surfaces?

Aerospace parts like fuel-system components typically feature complex part surfaces.

These complex surfaces feature various angles and holes of different sizes.

You require extremely powerful and technologically enhanced machines to machine the complex aerospace parts.

In general, 5-Axis CNC machining is preferred and proven effective against these surfaces.

The aerospace machining process aligns and begins the cutting process.

Through aerospace machining, handling complex part surfaces is quite easy and high-speed.

The precision aerospace machining features shorter cutters with high speed and accuracy.

The use of aerospace machining for complex part surfaces gives us:

● Longer tool life

● More durability and performance

● Better cutting fix orientation

● Produce better surface finish

● Improves accuracy

● Minimize the vibrations

● Programming is relatively simple

Complex surfaces require time to be perfectly machined, and a single mistake can be very costly.

Hence, you can eliminate the chances for errors to save cost and time through aerospace machining.

Complex part surfaces are not an issue or a challenge anymore, and through aerospace machining, you can achieve tighter tolerances for these parts.

How You Enhance the Quality of Aerospace Machining?

The proper use of raw materials, power, and other resources can enhance aerospace machining quality.

Aerospace machining capabilities range from the simplest 2-Axis CNC turning to complex and advanced 5-Axis CNC milling.

Following quality standards and adopting new and advanced aerospace machining techniques increase the overall quality.

Using the latest tool technology and state-of-the-art machinery improves the aerospace machining processes.

There comes the need to optimize the aerospace machining processes to achieve high-speed manufacturing.

Optimizing aerospace machining processes reduces the waste of raw materials. It eliminates the unnecessary steps involved in the complete part fabrication process.

It also means that you get cost-effective solutions and exceptional quality parts exactly based on your specifications that exceed your expectations.

At DEK, we improve efficiencies and reduce costs. DEK’s ultimate goal is to adopt new and emerging technologies to keep you completely satisfied.

Moreover, DEK enhances the quality of our aerospace machining process by:

● Using stronger, lightweight, and cost-effective material

● Operating at the highest speed without sacrificing the quality and precision

● Producing parts require tighter tolerances more efficiently

● Developing new methods by remaining up to date with technology

● Better processing of high complexity parts

DEK’s one quality that the aerospace industry appreciates is our skill and knowledge in this field, and the ability to produce is what you required.

What is the Role of CNC in Aerospace Machining?

CNC is a machine-driven cutting process based on advanced machining technologies.

The use of CNC machining in the aerospace industry is vast. In general, CNC machining is trusted the most for aerospace parts fabrication.

There were many advancements in this field, along with computer-aided design and manufacturing.

Aerospace CNC machining reduced the chance of human error to null and provide the precision and accuracy required by the standards set for aerospace parts.

These requirements contain a 3D CAD file that contains the design of the required aerospace part that requires machining.

CNC machining has little room for error. The nature of aerospace machining requires:

● Utmost Precision

● Tight Tolerances

● Extreme Accuracy

● Accountability

● Efficiency

● Handling Part Surface Complexity

● Rapid Fabrication

The aerospace parts are designed, fabricated, and configured using CNC machines.

Every aerospace engineering part requires utmost precision and a perfectly manufactured surface to ensure long life, high performance, longevity, and safety.

Is Aerospace Machining Expensive?

In the aerospace industry, aerospace machining is making progress with regard to overall costs.

Aerospace machining can be expensive for some applications, and for others, it can be extremely cheap.

The costs of aerospace machining mostly depend on your requirements.

Suppose you require extremely accurate and precise results with the use of high-grade materials and require tighter tolerances. In that case, aerospace machining can be expensive.

On the other hand, if you require standard aerospace parts that are not extremely complex, it can be cost-effective.

The complexity of the part also affects the overall aerospace machining cost. However, the aerospace machining cost can be removed by:

● Optimizing the Machining Process

● Reducing the Raw Material Waste

● Minimizing the Waste of Resources and Energy

● Utilizing Cost-Effective Raw Materials

● Reducing the Process Steps

● Increasing the Part Fabrication Speed

● Maintaining the Precision and Accuracy

● Reducing the Number of Defects

Moreover, the following factors can affect the aerospace machining cost:

● The Part Surface Complexity

● The Selection of Raw Material

● The Cutting Precision

● The Tighter Tolerances

● The Surface Finish

At DEK, we understand and value the importance of your need for high-quality solutions under minimum costs.

How Your Aerospace Machining Eliminates the Waste of Resources and Energy?

With the innovative and advanced aerospace machining technologies, part fabrication becomes resources- and energy-efficient.

At DEK, we adopt these aerospace machining technologies to eliminate waste and make our manufacturing eco-friendly and pollution-free.

Eliminating the waste of resources and energy is more profitable and cost-effective.

It is also possible by optimizing the aerospace machining process. At DEK, we eliminate the waste of resources and energy by:

● Implementing the latest technology

● Adopting advanced processes

● Volume reduction to efficiently manage waste

● Reducing the excess use of machining

● Eliminates safety issues

● Higher reduction to scrap volume

● Recovery of waste

● Reduction in hazardous waste handling costs

● Contributing to higher quality part production

● Eliminating risk

● Eliminating chances of error through accuracy

● Increase process consistency

Moreover, eliminating physical prototypes need can save resources and energy. Moreover, computer CAD models doing the same without costing thousands.

At DEK, we also use the right aerospace machining process based on your part design to maximize efficiency and efficiently make cuts.

It also reduces the excess scrap that is created during the manufacturing process and becomes the reason behind waste elimination.

How You Offer Aerospace Machining Design Freedom Without Sacrificing Performance?

At DEK, we believe that reducing the part weight increases its performance and improves part life.

DEK doesn’t want our customers to restrict themselves in design, so we also offer complete customization for your aerospace part’s design.

Flexibility is required to improve the design and manufacturing freedom of aerospace parts.

The accuracy and precision remain the same along with the part’s performance by increasing the design flexibility.

It’s cost-effectively possible to fully design a part of complex functionality without any design limitation through aerospace machining.

Aerospace parts with internal features or complex geometries can have benefited from our ability to process design of any shape and size.

Our advanced state-of-the-art technology and machinery enable us to manufacture bigger parts with utmost complexity.

The most efficient use of materials, process optimization, and design freedom eliminate the manufacturing constraints without disturbing its performance.

Our aerospace machining is capable of optimizing your part design to a level at which its weight can even reduce up to 25% from its base structure.

How You Offer the Best Aerospace Machining Services?

DEK has spent years becoming one of the best, and premium aerospace machine shop focusing on manufacturing parts requires tightest tolerances and contain extreme complexity.

DEK knows that aerospace machining’s extremely critical nature contains an exceptional amount of detail and requires a high level of attention from our years of field experience.

At DEK, we offer precision aerospace machining and capable of holding extremely tight tolerances even up to ±0.001.

DEK also offers complete customization and freedom of your part design through our high-speed aerospace machining processes.

All our aerospace machining services cost-effectively ensure rapid deliveries while maintaining the highest quality and performance level.

DEK completely controls our aerospace machining environment so that there cannot even be a slim chance for an error.

There are five reasons why our customers believe that DEK is the right aerospace manufacturer for them:

● DEK is a robust aerospace machining facility with the resources to support your every need related to the aerospace industry

● DEK has the right aerospace machining equipment and technology to support you

● DEK has a standard and controlled environment that helps you get the low-cost and high-quality aerospace machined parts

● DEK is based in China and offers its services internationally without any restrictions

● DEK offers efficient and low-cost shipping with proper packaging after detailed quality testing of your order.

What are Your Aerospace Machining Capabilities?

DEK is expertise in aerospace machining and specialized in fabricating precision parts with complex geometries.

DEK is capable of understanding your needs and can overtake every related challenge.

Moreover, DEK doesn’t make mistakes here and offer cost-effective solutions, even for your complex parts that require tighter tolerances.

Our focus is on machine parts with utmost quality, reliability, and performance without any room for error.

Our capabilities include:

● Quality product design

● Precision aerospace machining

● Innovative solutions to enhance productivity

● Reduce overall costs

● Standard aerospace machining services

At DEK, we can manufacture aerospace parts like oil tanks, engine components, landing gear, filtration and fuel panels, and many more through our aerospace machining.

Furthermore, DEK also offers complete customization of your aerospace parts from its 3D CAD design to its testing.

Through DEK, you can have the following unmatched advantages:

● DEK offers complete aerospace machining services

● DEK offers CNC machining flexibility

● Our technologically enhanced capabilities meet complex and high-volume requirements

● DEK offers quality, performance, and reliability

● Closely monitor each aerospace machining process

● Offer extreme purity, tighter tolerances, and precision

Moreover, our 5-Axis CNC machining allows the fabrication of extremely difficult parts rapidly.

At DEK, we will make your job our priority and ensure the finest quality.

Can You Sign a Confidentiality Agreement?

In short, yes! In order to protect your sensitive information, DEK offers a choice of a confidentiality agreement.

DEK will protect your information at any cost and will keep it out from any discussion or report.

Our confidentiality agreement will cover and protect any information we exchange during our project.

DEK doesn’t offer a limited amount of agreement rules, and our confidentiality document is completely flexible. DEK will protect your assets with the utmost care.

As an international client, you have to be cautious over handling your critical information to manufacturers in China; DEK will offer you the choice of a confidentiality agreement.

It’s for your satisfaction; otherwise, DEK ensures your documents’ safety in all conditions.

As well as, DEK will keep your information secret and offer you the satisfaction you required from us.

How to Order from DEK?

DEK is a one-stop and high-quality aerospace machine shop that offers its services on demand.

DEK offers its services to the ones who are committed to achieving high-quality and accurate parts in cost-effective manners.

At DEK, our staff will be available anytime to facilitate you in-case you require more information or have any questions.

Moreover, we facilitate you through our “Request a Quote” option to detail study your design & complete order and give the aerospace machining services exactly as you desired.

DEK requires some basic information and a 2D/3D file containing the design of your required part to discuss it further and give you the perfect material, quality, performance, surface finish, tolerance, price, and hardness through our rapid aerospace machining.

Our 19+ years of field experience enabled us to process any order from simplest to extremely complex in a cost and timely manner.

Most importantly, DEK’s integrated approach to quality control is the guarantee that your order is perfectly machined.

After a successful quote and a successful agreement, we will start manufacturing your order.