Service

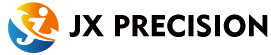

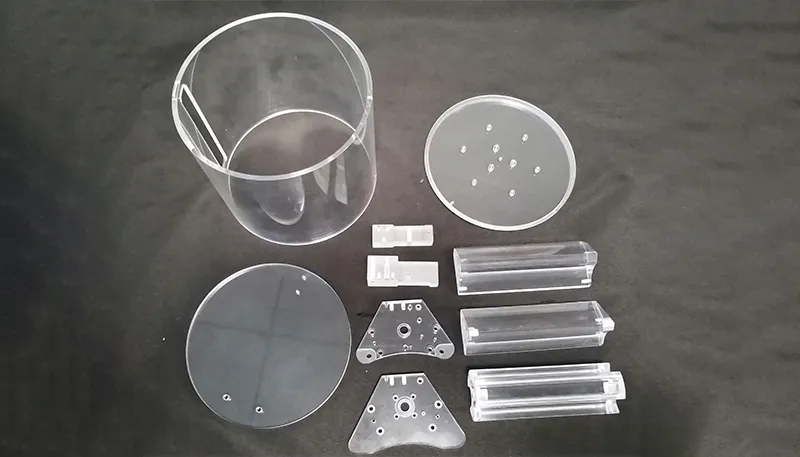

Plastic Injection Molding Services

JX is a world-class provider of advanced plastic injection molding services. We offer a complete manufacturing solution that covers every aspect of raw material verification, tool making, part fabrication, finishing, and final inspection. Our international team of manufacturing experts is committed to providing you with the highest level of professional support for plastic injection molding services of any size or complexity.

The Plastic Injection Molding Process

Plastic injection molding is the process of filling a mold tool with liquid plastic resin under great pressure. The tool may comprise a single cavity or hundreds of cavities in order to make indefinite numbers of parts. Once the mold tools have been carefully designed and manufactured, the molding process consists of the following basic steps:

● Step 1 – The plastic resin comes in raw pellets. These are dried to the right moisture content, and then if necessary they can be blended with pigments or master batch colorants to create the correct color for the design.

● Step 2 – The dried pellets are poured into the hopper of the molding machine. A reciprocating screw inside the barrel of the machine is used to transport these pellets towards the mold while at the same time heating them.

● Step 3 – Within the barrel, the pellets are mixed and heated until fully molten, forming the liquid resin.

● Step 4 – The heated mold closes automatically and resin, under great pressure, is injected through a gate and into the mold cavity.

● Step 5 – The mold is cooled in a short amount of time to solidify the part inside.

● Step 6 – The mold opens and the part is ejected to begin a new cycle.

Advantages Of Plastic Injection Molding

There are many advantages to plastic injection molding. These include the ability to make large volumes of parts quickly, high surface quality, many resins to choose from, color flexibility, and durable tooling that can last for years.

Why Choose JX for Plastic Injection Molding

The finest production mold tools start with quality raw materials, strict process control, and expert toolmakers. Only a supplier with years of experience supporting Fortune 500 companies can ensure repeatable results for your production tooling needs. Here are some of the advantages that JX offers for high-volume production tool making and injection molding services.

A Complete Range of Services

We offer more than just tool making and molding services. Our complete package includes every manufacturing process you need for a total product development solution.

Proven Success

Thousands of companies of every size from around the globe have chosen to work with JX to help them develop new injection mold tools and finished parts. Your success is the foundation of our reputation.

Positive Material Identification

Your regulatory compliance and your peace of mind are assured with our industry-leading positive material identification department. People trust JX when the job absolutely must be right.

Design Optimization

A comprehensive design for manufacturing review comes with every tool and product design project. You’ll receive superior results while saving time and money.

Intelligent Quotations for Every Project

We support your development goals by having no minimum order volumes or value for our injection molding production. In addition, we have a proprietary AI quoting algorithm that provides fast, accurate, and transparent pricing on every project, every time.

Applications for Plastic Injection Molding

Plastic Injection in the Medical Industry

Plastic is very useful in the medical field. Resins are lightweight, non-toxic, inexpensive and can be reused or recycled. Applications include syringes, catheters, dispensers, tubing, and other appliances. For more information about plastic injection molding in the medical field, read our blog post.

Plastic Injection in the Medical Industry

Plastic is very useful in the medical field. Resins are lightweight, non-toxic, inexpensive and can be reused or recycled. Applications include syringes, catheters, dispensers, tubing, and other appliances. For more information about plastic injection molding in the medical field, read our blog post.

- Phone:+1 (859) 254-6589

- Email:info@example.com

Plastic Injection in Consumer Products

We use plastic every day for work and play. Plastic compounds with different chemical properties are found in computer keyboards and mice, game controllers, headphones, toys, home appliances and kitchen gadgets – anywhere you look. Learn more about plastic used for consumer products.

Plastic Injection in Consumer Products

We use plastic every day for work and play. Plastic compounds with different chemical properties are found in computer keyboards and mice, game controllers, headphones, toys, home appliances and kitchen gadgets – anywhere you look. Learn more about plastic used for consumer products.

- Phone:+1 (859) 254-6589

- Email:info@example.com

Plastic Injection in the Electronics Industry

Components like circuit boards, switches, wires, batteries, and sensors must be placed in strong, lightweight, non-corrosive, and non-conductive housings to protect them while also safeguarding the user. Learn why plastic injection molding is an ideal solution to support the electronics industry.

Plastic Injection in the Electronics Industry

Components like circuit boards, switches, wires, batteries, and sensors must be placed in strong, lightweight, non-corrosive, and non-conductive housings to protect them while also safeguarding the user. Learn why plastic injection molding is an ideal solution to support the electronics industry.

- Phone:+1 (859) 254-6589

- Email:info@example.com

Plastic Injection in the Agriculture Industry

Plastic products used in agriculture must be strong and durable, able to resist UV light and chemicals. Engineered plastic parts are used in conveyor belts, drive trains, feeders, water sprinklers, fencing, tools, and much more. Learn why plastic injection is a great solution for the agriculture industry.

Plastic Injection in the Agriculture Industry

Plastic products used in agriculture must be strong and durable, able to resist UV light and chemicals. Engineered plastic parts are used in conveyor belts, drive trains, feeders, water sprinklers, fencing, tools, and much more. Learn why plastic injection is a great solution for the agriculture industry.

- Phone:+1 (859) 254-6589

- Email:info@example.com

Plastic Injection Molding Tolerances

Plastic resins expand and contract because of temperature, mechanical stress and moisture. Our manufacturing tolerance guide gives you general information on the shrinkage characteristics of most common resin types to help guide your design decisions.

As part of our design analysis, we’ll indicate any areas that might produce thermal stress, shrinkage, warping, or other avoidable defects in your injection molded parts. For more information, consult our manufacturing design guide on common defects and how to avoid them.

As part of our design analysis, we’ll indicate any areas that might produce thermal stress, shrinkage, warping, or other avoidable defects in your injection molded parts. For more information, consult our manufacturing design guide on common defects and how to avoid them.

Unless otherwise specified, we comply with the DIN 16742 standard tolerances for injection moldings. Ensuring the highest quality is an important part of our production process. Be sure to read about the visual quality standards guide that we apply to injection molded parts.

Quote Now to Start Your CNC Machining Project

Complete CNC machining services from prototype to production ensure high quality, fast delivery and competitive prices.